We will be closed for lunch from about 11:15 to 2:30 on March 28, 2024 to celebrate the end of our 35th year in business.

Category: Uncategorized

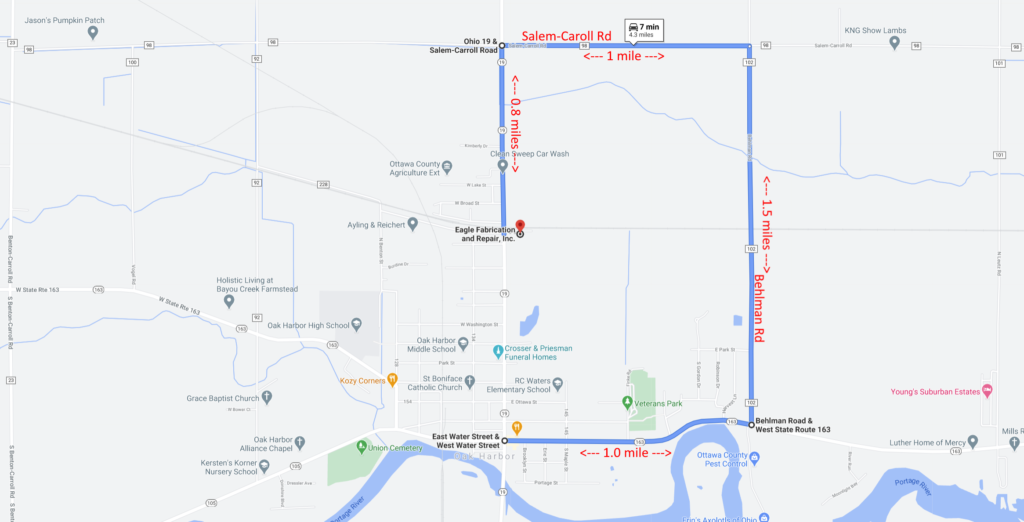

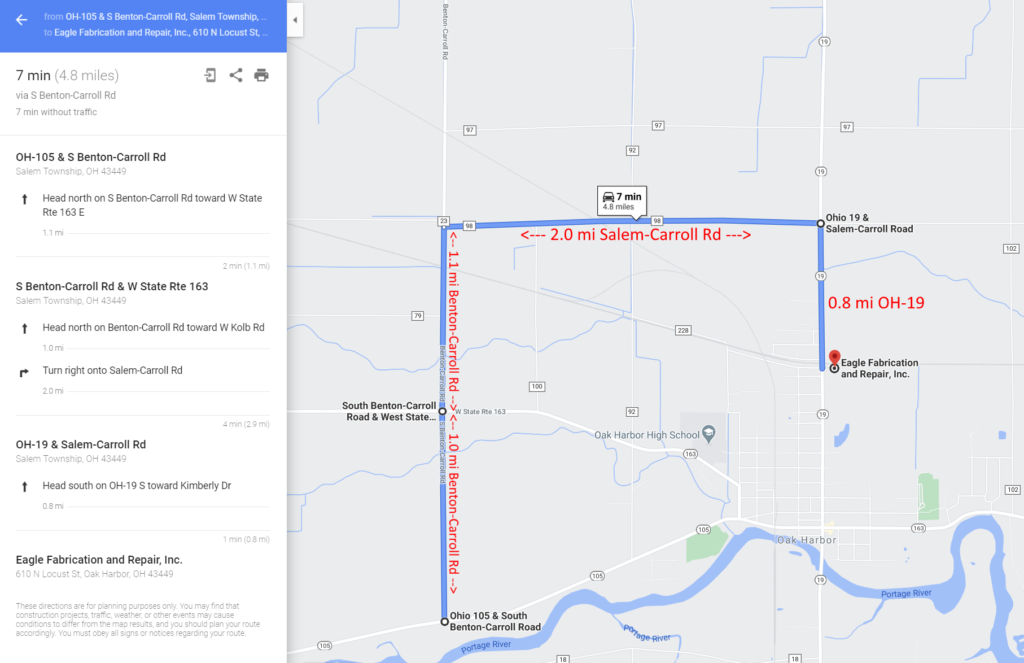

Detour / Road Closed July 2023

UPDATE July 31, 2023

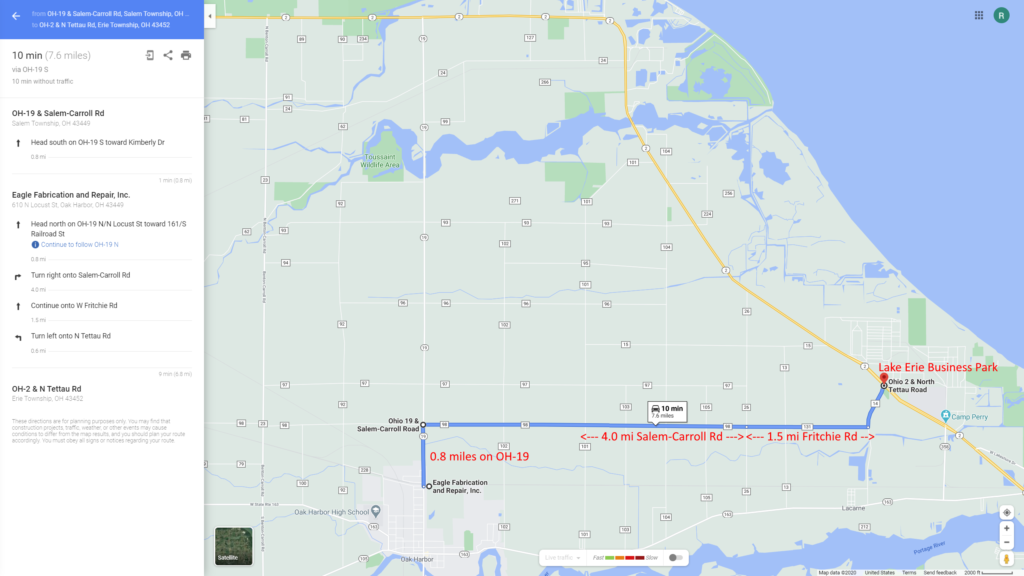

State Route 19 in Oak Harbor will be closed again, north of SR 163, for 5 days for resurfacing. However, the asphalt plant was struck by lighting causing a delay in the work. Date of reopening is unknown.

Plan to come to our location from the North, travelling south on State Route 19. Below are three ways to get to our business and avoid the road closures.

UPDATE July 5, 2023Beginning Wednesday, July 5 there is a road closure of OH-19 between downtown Oak Harbor and our location. Both 19 and 163 are closed in town. Plan to come to our location from the North, travelling south on State Route 19. Below are three ways to get to our business and avoid the road closures.

State Route 19, between Mill St. and Main St., Oak Harbor, will be closed for intersection reconstruction. SR 163 will also be closed at the intersection. The closure will happen over two separate occurrences on either side of the Ottawa County Fair.

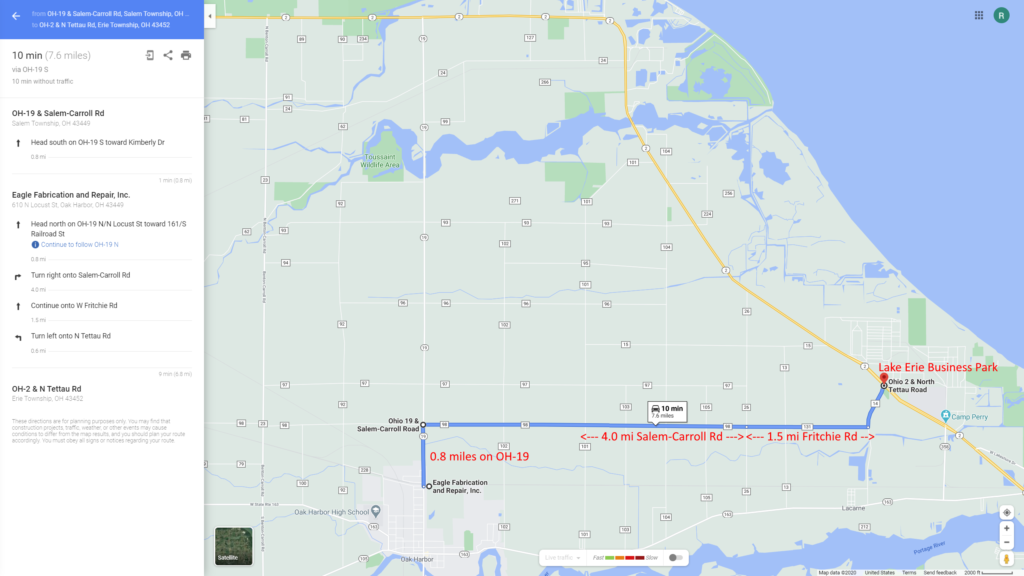

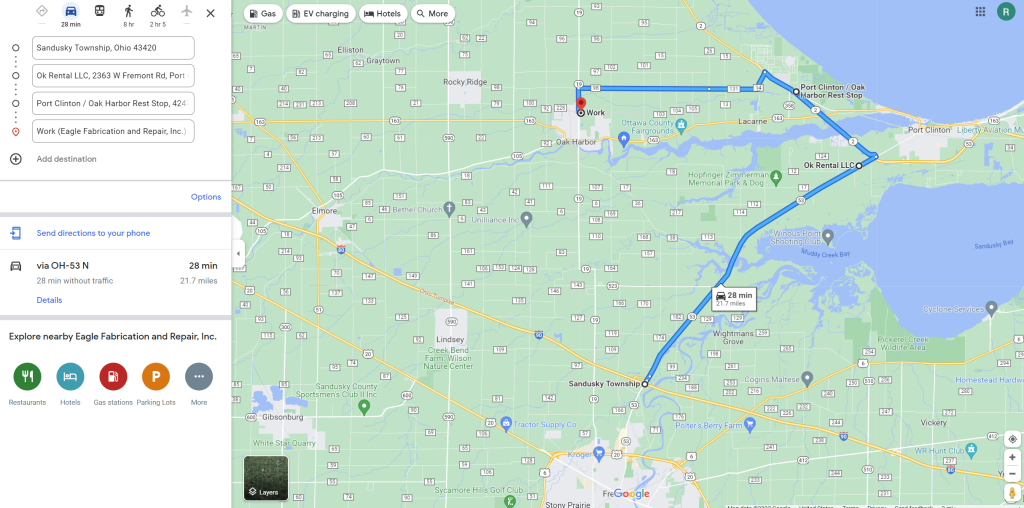

From the North or North/West: Take State Route 19 south from State Route 2

Detour / Road Closed 2021

UPDATE July 2023: Yet another closure. Please see Detour / Road Closed July 2023 for updated maps because you cannot come in 19 across the river in town.

UPDATE April 2, 2021

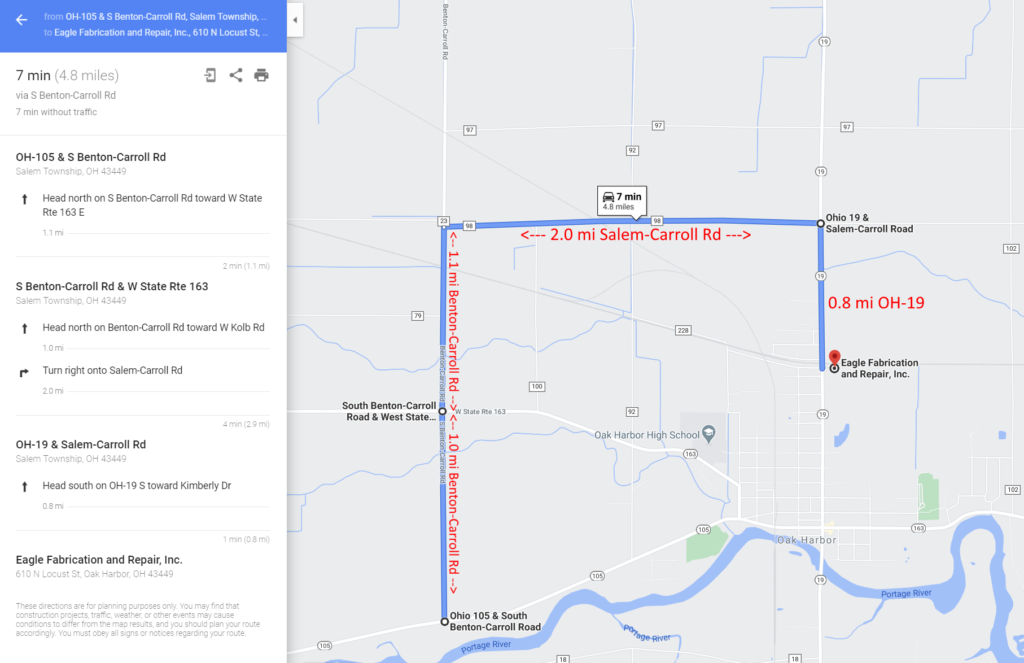

Beginning Friday April 9, 2021 for 45 days (until about June 3, 2021) there is a planned road closure of OH-19 between downtown Oak Harbor and our location. Plan to come to our location from the North, travelling south on State Route 19. Below are three ways to get to our business and avoid the road closures.

UPDATE Nov 1, 2020: The roads that were closed in August 2020 are now open. We are leaving these maps here in case you need to reference them in the future. Thank you for your patience with the construction!

As of Monday August 31, 2020 there is currently a road closure of OH-19 in downtown Oak Harbor and also another one on OH-19 farther North. These are three ways to get to our business and avoid the road closures.

From the East: https://goo.gl/maps/3aAFC8bq4wph8EnW7

From the South: https://goo.gl/maps/tK6agLSX7Lqm3cen9

From the West: https://goo.gl/maps/zhXBM6rR5PeNu72Q7

When is a pressure test (hydrotest) due?

MC 331 cargo tanks less than 3,500 gallons water capacity in dedicated propane service constructed of NQT SA-612 steel: 10 year intervals

Uninsulated MC 331 cargo tanks in dedicated propane service: 5 year intervals

The rule in 49 CFR § 180.407 was amended July 18, 2018 to remove confusion and states “the 10-year inspection period for eligible CTMVs applies from the date the most recent pressure test and internal inspection were performed.” In 2017 that was not clear.

Run all your trucks every year

A cargo tank that has been out of hazardous materials transportation service for a period of one year or more must be pressure tested prior to further use according to 49 CFR § 180.407, so deliver with your backup truck too.

Date Markings

Please check the right date. We sometimes find tanks incorrectly marked with only a “retest” date instead of correctly marking the date the test was performed.

Disclaimer: Information is provided for general informational purposes only and should not be construed as legal advice.

Pump Cavitation Facts, Causes & Remedy

Propane bobtails equipped with positive displacement sliding vane pumps have always experienced some level of pump cavitation. This cavitation results in noise, vibration and reduced delivery rates. The simple explanation of the reason for cavitation is that the bobtail delivery system is unvented so the removal of product from the bobtail tank results in a tank vacuum causing pump starvation. This problem has been tolerated over the years as there was no known practical remedy.

In the case of a bobtail propane delivery, the physics involved is not quite as simple as stated above. Liquid propane stored in a pressure vessel is stabilized at its boiling point based on the ambient temperature of the propane. To explain further, the actual boiling point of propane is −44 °F. So if it was −44 °F outside, you could contain and transport propane in a bucket as if it was water. Because it is seldom that cold we store propane in pressure vessels. Liquid propane that is stored above −44 °F boils to produce propane vapor. Each gallon of liquid propane when boiled into the vapor state produces 270 gallons of vapor propane. The boiling of liquid into vapor fills the vapor space of the containing vessel pressurizing the vessel. The pressure developed in the containing vessel is directly proportional to the ambient temperature of the liquid propane. Examples of pressures for various temperatures are as follows. −44 °F = 0 psi, 0 °F = 28 psi, 32 °F = 60 psi, 70 °F = 120 psi, 100 °F = 190 psi. The result is the boiling point of propane is increased as the containment pressure increases. This increase in the boiling point explains how the liquid is stable in storage. Propane automatically maintains stability in the pressure vessel. If the temperature cools down some, vapor in the vapor space will condense into liquid to reduce the pressure. If the temperature warms up, some of the liquid propane will vaporize to pressure up the vessel.

Now that we understand how a propane vessel becomes pressurized, we can examine what happens when we remove propane from that vessel. If we open a vapor or liquid valve and remove propane from the vessel, the remaining liquid propane will boil to replenish the vapor pressure. This will cause the liquid propane to cool as it vaporizes. Just like boiling a pot of water on a stove, this boiling action requires heat. The heat required to boil the propane is conducted thru the vessel wall from the surrounding air. If the heat transfer thru the vessel wall is not rapid enough to maintain the vessel pressure, the remaining liquid will cool and the pressure will fall. The larger the percentage of liquid in the vessel, the more liquid is available to boil. The smaller the percentage of liquid remaining in the vessel the more vigorously it must boil to replenish the vapor pressure. Following the same physics, the warmer the ambient air, the more heat is available to boil the propane and the colder the outside air, the slower the boiling process.

How does all of the above explain the noise and vibration associated with a propane delivery from a bobtail? When the delivery is started, the stable propane is forced thru the main internal valve and into the pump primarily by gravity. As soon as propane is removed from the vessel the pressure in the vessel begins to fall and the remaining liquid begins to boil to replenish the pressure. The rate of boiling is affected by the rate of discharge, the amount of remaining liquid available to boil and the outside air temperature which is the primary source of heat to sustain the boiling. The noise and vibration results from the vapor bubbles generated in the boiling liquid propane being drawn into the pump. Bobtail propane pumps are all sliding vane positive displacement pumps. They use a combination of centrifugal force, pushrods and hydraulic pressure to maintain the sliding vane seal within the pump. These vapor bubbles cause the hydraulic sealing action of the pump blades to be disrupted causing the blades to chatter. Additionally the collapsing of the vapor bubbles back into liquid as the pumping action pressurizes the propane to force it thru the piping, generates much noise and vibration. Now all of the above factors begin to play a role. The faster the rate of delivery, the faster the rate of boiling. The less remaining liquid in the bobtail vessel, the faster it must boil and finally the colder the outside air, the less heat is available to accomplish the boiling. Propane is a volatile product and will vigorously boil until it reaches −44 °F. If there is insufficient heat available to support the boiling then the vapor pressure in the vessel will fall. As the pressure falls in the bobtail vessel, the pump is starved for product. Pumps don’t make much suction but they make some and that suction further pulls the liquid, coming thru the internal valve, apart creating more vapor bubbles. This pump starvation leads to loss of delivery pressure and slowed delivery rates.

Is there a remedy? The answer is, there are several, but most are not economically or legally feasible:

- Hooking up a vapor return line from the receiving vessel will solve the problem. The down side to this is it takes a lot of time and it is illegal to return vapor without measuring how much is returned.

- Only make small deliveries from a full truck so there is plenty of liquid in the truck and a good gravity push to keep the pump well fed. Economically not feasible as this requires many unproductive trips to reload the bobtail.

- Make all deliveries at a reduced pumping rate so the remaining liquid in the bobtail can get enough heat from the outside air to maintain vessel pressure. This is also economically not feasible.

- Find an alternative heat source for the remaining liquid in the bobtail vessel. This can be an economically feasible remedy.

Liquid to liquid heat exchangers available today can use available engine coolant heat to heat the remaining liquid in the bobtail vessel. Adding this additional heat to the heat available from the outside air is enough to maintain the stability and vapor pressure in the bobtail tank during a propane delivery.

Eagle Fabrication can install a heat exchanger system on your bobtail for about $2000.00. What can you expect from this system? Zero increase in noise and vibration as the delivery progresses. Our testing demonstrates if the delivery begins at a noise level of 86 decibels it will finish at 86 decibels, in fact no pump cavitation noise will be heard until the vessel goes empty. Additionally, many bobtails begin a delivery at 65 gpm that falls off to 45 gpm at the end of a 500 gallon delivery. Our heat exchanger testing of pump delivery rates usually only record a loss of 3 gpm or less from start to finish on 1000 gallon delivery.

Contact Eagle Fabrication to reduce the noise and vibration and improve the efficiency of your bobtail. Only time will tell how this upgrade will improve the life of the pump, reduce vibration/stress cracks, reduce fractured wiring failures especially in electronic registers and possibly even reduce LED light bulb failures due to vibration.